A number of factors affect the ability of a measurement system to discriminate among the units it measures. These factors can be categorized generally into those that affect central location and those that affect the variability (spread) of the measurements. Variability factors measured by repeatability and reproducibility are the more familiar, while factors related to the central location of the measurements (stability, bias, and linearity) are relatively new approaches. Both approaches may need clarification. In addition, methods of measurement must be developed along with standards for indicating their acceptability. In a series of articles, these concepts will be addressed.

The first of these will deal with repeatability and reproducibility and combining them into the R&R component. The next article will take this R&R component and calculate R&R percentages based on study variation, process variation, and tolerance. The Measurement Study (classic) typically utilizes one to three appraisers for one measuring instrument that is measuring a single characteristic. Each appraiser measures five to ten units selected from a process two or three times (replications). Before proceeding with the analysis of the study, the ranges for the replications of the measurements made by each appraiser on each part are determined and used to calculate control limits for the range chart. Then each range is checked to determine if it falls inside the limits. Those measurements that result in a range outside the limits should be excluded from further analysis or should be redone. Operative assumptions include:

- The measuring instrument stays in calibration (central location does not change);

- Appraisers use the same method of measurement;

- Parts are measured in the same place. (If the assumption that the parts are measured in the same place is incorrect, the possibility of within-part variation will need to be considered.)

Repeatability refers to the variation in measurements for one characteristic made with one measuring instrument by one appraiser on the same part. An estimate of repeatability is obtained by first determining the average range ( ) of the repeated measurements of the same characteristic, using the same measuring instrument for several parts. Note: if more than one appraiser is used in the study, the average range is the combination for all appraisers, e.g., [If there are three appraisers, a, b, and c, you would determine the average range using (

) of the repeated measurements of the same characteristic, using the same measuring instrument for several parts. Note: if more than one appraiser is used in the study, the average range is the combination for all appraisers, e.g., [If there are three appraisers, a, b, and c, you would determine the average range using ( =

=  a +

a +  b +

b +  c )/3]. Next, the standard deviation for the repeatability (se) is estimated by dividing

c )/3]. Next, the standard deviation for the repeatability (se) is estimated by dividing  by d*2. A 99% (-2.575 < z < +2.575) interval for repeatability is determined by multiplying 5.15 by (se).Reproducibility refers to the difference in the average of the measurements on one characteristic made by different appraisers using the same measuring instrument on the same part(s). Note: if there is only one appraiser using the gage, there will be no reproducibility (appraiser variation). Again, the assumptions are that the instrument stays in calibration, the appraisers use the same method of measurement, and the part is measured in the same place. An estimate of reproducibility is obtained by determining the mean of all the measurements made by each appraiser e.g., [If there are three appraisers, a, b, and c, you would determine the average range using (

by d*2. A 99% (-2.575 < z < +2.575) interval for repeatability is determined by multiplying 5.15 by (se).Reproducibility refers to the difference in the average of the measurements on one characteristic made by different appraisers using the same measuring instrument on the same part(s). Note: if there is only one appraiser using the gage, there will be no reproducibility (appraiser variation). Again, the assumptions are that the instrument stays in calibration, the appraisers use the same method of measurement, and the part is measured in the same place. An estimate of reproducibility is obtained by determining the mean of all the measurements made by each appraiser e.g., [If there are three appraisers, a, b, and c, you would determine the average range using ( =

=  a +

a +  b +

b +  c )]. The range estimate for the operators (Ro) is obtained by subtracting the minimum

c )]. The range estimate for the operators (Ro) is obtained by subtracting the minimum  i from the Maximum

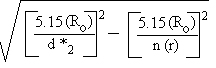

i from the Maximum  i.Next, the standard deviation for reproducibility (so) is estimated by dividing (Ro) by d*2. Again, a 99% (-2.575 < z < +2.575) interval for repeatability is determined by multiplying 5.15 by (so).Since the measuring instrument is used in making the measurements, it is a contributing factor to the calculation of reproducibility. Therefore, the calculation of reproducibility needs to be adjusted by subtracting a portion of repeatability. The adjusted appraiser variation is given by:

i.Next, the standard deviation for reproducibility (so) is estimated by dividing (Ro) by d*2. Again, a 99% (-2.575 < z < +2.575) interval for repeatability is determined by multiplying 5.15 by (so).Since the measuring instrument is used in making the measurements, it is a contributing factor to the calculation of reproducibility. Therefore, the calculation of reproducibility needs to be adjusted by subtracting a portion of repeatability. The adjusted appraiser variation is given by:

Where:

n = number of parts used in the study

r = number of times each part is used

R&R is the combination of repeatability and reproducibility variation and frequently is considered as the total measurement variation excluding within part variation and variation in central location. R&R studies can be done easily and accurately using software products like GAGEpack.